|

| |

Home

:: Biodegradable Plastics |

The new generation plastics fully degradable from symphony

environmentals offers considerable advantages such as increased

landfill capacities by 20-30% and can be engineered to degrade

in as little as 60 days or over 5 years to suit end required

application.

The process of degradation is through the breakdown of carbon-carbon

bonds in the polyethylene reducing the molecular weight down

to the level of 4000 from a quarter million, at which point

the material can be digested by microorganisms in the soil

and water. The DCP additive is neither water soluble nor toxic

and hence safe for disposal in landfill sites.

The materials is also degradable under other conditions viz.

photo and thermal degradation. The bags degrades to mulch

in just 55 days.

The new polyethylene promises extensive applications that

include small produce bags, carrier bags, industrial products

packaging and even degradable plastic aprons. Refuse sacks

are already in the market.

Biodegradable Polyester Amide

BAK, a semi-crystalline largely transparent thermoplastic

developed by Bayers is a new biodegradable polyester amide

plastic claimed to be 100 percent biodegradable and recyclable

with excellent properties including high tensile produced

without solvents, chlorine or any aromatic ingredients, adds

to its green credentials. The biodegradability is achieved

as it breaks down into carbondioxide, water, biomass under

composting conditions. The rate of degradation is similar

to other organic materials and properties similar to typical

polyolefins. The new developed material also seem to be amenable

to various process conversions that include extrusion, blow,

thermoforming, colouring, printing etc., Applications are

extensive including agrihorticulture and food etc.,

Recycling regulations have spurned ecologically safe consumer

friendly bioplastics. The leading chemical industry in Germany,

BASF is testing food bags and packaging from its ecoflex bioplastic

which contains a biodegradable petrochemical polymer.

The latest development of bioplastic in Australia lends itself

to biodegrade at temperatures as low as 0.5 degrees Celsius

or mere exposure to moisture and micro organism in the soil.

The technology appears to be unique as ascertained by Biodegradable

Institute in New York.

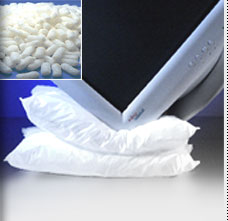

Plastics has patented its development of the polymeric looking

material - that looks, feels and is flexible like any conventional

plastic. The process uses standard industrial extruders to

produce cornstarch based pallets and can be converted by blowing

and moulding. The prices are comparable to petroleum based

plastics. However, the drawback of inadequate product preservation

under adverse conditions need to be overcome. This could add

to the cost and thus the costs should come down for plastic

to expand and reach out wider markets. The market trials by

leading multinational food companies should provide the lead

for further developments.

«

Prev

|