|

| |

Home

::Biodegradable Plastics |

News Item:

Immediate application areas identified in India for biodegradable

plastics are Agricultural Mulch, Surgical implants, Industrial

Packaging, Wrapping, Milk Sachets, Foodservice, Personal care,

Pharmaceuticals, Medical devices, recreational etc.

Biodegradable Plastics highlights the Indian efforts in the

direction, as well as activities at some of the major centers

of developmental at USA/Canada, Germany, Scandinavian countries

and Japan.

Plastics that break down

In an effort to overcome these shortcomings, biochemical researchers

and engineers have long been seeking to develop biodegradable

plastics that are made from renewable resources, such as plants.

The term biodegradable means that a substance is able to be

broken down into simpler substances by the activities of living

organisms, and therefore is unlikely to persist in the environment.

There are many different standards used to measure biodegradability,

with each country having its own. The requirements range from

90 per cent to 60 per cent decomposition of the product within

60 to 180 days of being placed in a standard composting environment.

The reason traditional plastics are not biodegradable is because

their long polymer molecules are too large and too tightly bonded

together to be broken apart and assimilated by decomposer organisms.

However, plastics based on natural plant polymers derived from

wheat or corn starch have molecules that are readily attacked

and broken down by microbes.

Biodegradable plastics made with plant-based materials have

been available for many years. Because of their higher cost

they have never replaced traditional non-degradable plastics

in the mass market.

Indeed, biodegradable plastic products currently on the market

are from 2 to 10 times more expensive than traditional plastics.

But environmentalists argue that the cheaper price of traditional

plastics does not reflect their true cost when their full

impact is considered. For example, when we buy a plastic bag

we don't pay for its collection and waste disposal after we

use it. If we add up these associated costs, traditional plastics

would cost more and biodegradable plastics might be more competitive.

Biodegradable and affordable

If cost is a major barrier to the uptake of biodegradable plastics,

then the solution lies in investigating low-cost options to

produce them.The Cooperative Research Centre (CRC) for Food

Manufacture and Packaging Science is looking at ways of using

basic starch, which is economical to produce, in a variety of

blends with other more expensive biodegradable polymers to produce

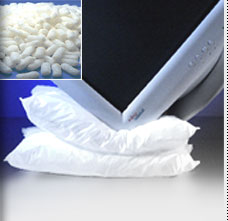

a variety of flexible and rigid plastics. These are being made

into 'film' and 'injection moulded' products such as plastic

wrapping, shopping bags, bread bags, mulch films and plant pots.

Mulch film from biodegradable plastics

The CRC has developed a mulch film for farmers. Mulch films

are laid over the ground around crops, to control weed growth

and retain moisture. Normally, farmers use polyethylene black

plastic that is pulled up after harvest and trucked away to

a landfill (taking with it topsoil humus that sticks to it).

However, field trials using the biodegradable mulch film on

tomato and capsicum crops have shown that it performs just as

well as polyethylene film but can simply be ploughed into the

ground after harvest. It's easier, cheaper and it enriches the

soil with carbon.

Pots you can plant

Another biodegradable plastic product is a plant pot produced

by injection moulding. Gardeners and farmers can place potted

plants directly into the ground, and forget them. The pots will

break down to carbon dioxide and water, eliminating double handling

and recycling of conventional plastic containers.

Different polymer blends for different products

Depending on the application, scientists can alter polymer mixes

to enhance the properties of the final product. For example,

an almost pure starch product will dissolve upon contact with

water and then biodegrade rapidly. By blending quantities of

other biodegradable plastics into the starch, scientists can

make a waterproof product that degrades within 4 weeks after

it has been buried in the soil or composted.

Composting the packaging with its contents

Compost may be the key to maximizing the real environmental

benefit of biodegradable plastics. One of the big impediments

to composting our organic waste is that it is so mixed up with

non-degradable plastic packaging that it is uneconomic to separate

them. Consequently, the entire mixed waste-stream ends up in

landfill.

By ensuring that biodegradable plastics are used to package

all our organic produce, it may well be possible in the near

future to set up large-scale composting lines in which packaging

and the material it contains can be composted as one. The resulting

compost could be channeled into plant production, which in turn

might be redirected into growing the starch to produce more

biodegradable plastics.

An Olympic effort - recycling 76 per cent of waste

For anyone who thinks such schemes aren't feasible, you only

have to look at the recycling success of the Olympics to see

that where there's a will, there's a way. More than 660 tonnes

of waste was generated each day at its many venues. Of this,

an impressive 76 per cent was collected and recycled. Part of

this success was due to the use of biodegradable plastics used

in the packaging of fast food, making the composting of food

scraps an economic proposition as it eliminated the need for

expensive separation of packaging waste prior to processing.

With intelligent use, these new plastics have the potential

to reduce plastic litter, decrease the quantities of plastic

waste going into landfills and increase the recycling of other

organic components that would normally end up in landfills.

Next

»

|